FAQ

The Rebuilding Process

Step by step process of what we do.

1.

This is the cooling unit before we start. It fits a Norcold 6cu.ft. refrigerator. It has some visable rust but is otherwise in good condition. At 14 years old, it has quit cooling.

2.

On all Norcold refrigerator units there is no charge port, just a stem that is welded shut. In order for me to charge this unit I have to cut off the stem and replace it with a new charge port.

3.

The new port is now welded into place and the unit is completely drained of all coolant.

4.

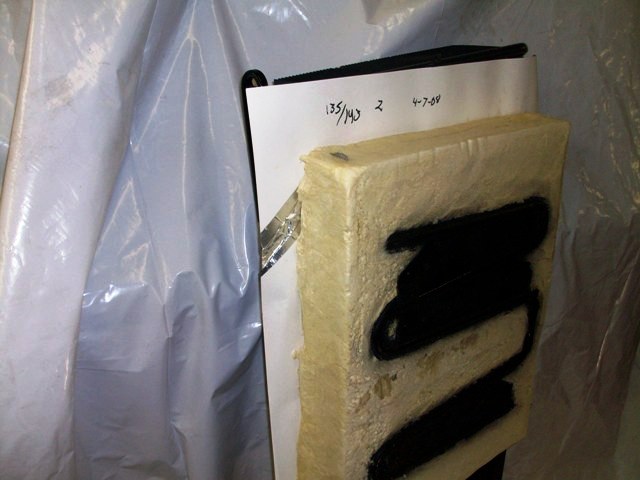

The foam pack is then removed and the evaporator coils are checked for damage.

5.

Here you can see that the cooling unit has extensive rust damage inside the foam, even though it looked good outside.

6.

The cooling unit is now sandblasted in preparation for a new evaporator.

7.

The old evaporator has now been cut out and removed.

8.

The old and new evaporator sitting side by side.

9.

The new parts are made ahead and kept in stock.

10.

The new evaporator is then welded into place onto the cooling unit.

11.

The new liquid line is then bent into shape and installed onto the new evaporator. The evaporator coils are now complete. We then proceed to reinforcesome of the old tack welds and braces to insure the unit is extra sturdy.

12.

The cooling unit is then completely flushed out. It is then vacumed down and charged. In order to insure the longevity of the cooling unit the charge has to be as perfect as possible. Our charging process has been perfected by years of experience and experimentation, making it possible for our rebuilt cooling units to outperform the original.

13.

The cooling unit is then tested for leaks. If none are found it is then painted white and then tested for performance.

14.

The completed unit with a new foam pack and ready for install.